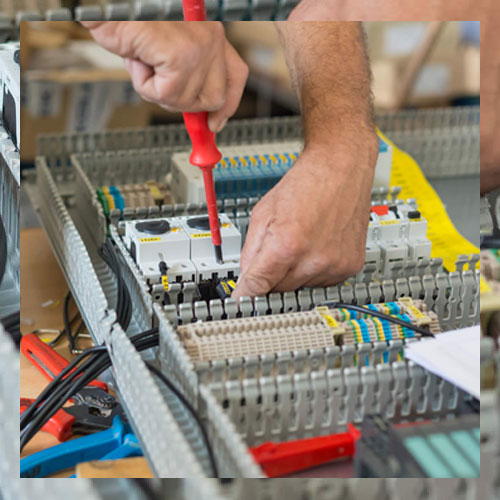

PRODUCTION

What we do?

PRODUCTION

COATING PROCESS

The most important and sensitive operation is electro static powder coating with passivation in production line. Corrosion and aging resistances of cabinets of WEPAN is increased. Before powder coating, each enclosures are passivated as surface cleaning with phosphate coating. Enclosures are coated electrostatic powder paint and ovened under the international standards.